Description

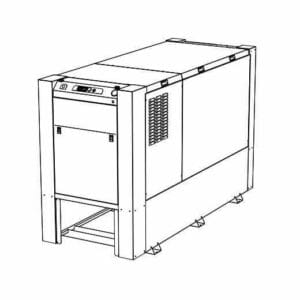

The S series Chillers are designed to cool processes with small heat loads.

They can be installed indoors or outdoors and can be configured to supply chilled water for

- Potable water applications

- Process cooling from an internal buffer tank

- Process cooling to an external buffer tank

Features

The chillers are supplied with – as standard

- An internal 40L buffer tank to protect the compressor from excessive start, close temperature tolerance, reduces thermal spikes and allows for vented design with no need for hydronics kit

- Suitable for indoor or outdoor installation

- Rugged galvanized steel construction

- Components sourced from the industries leading suppliers

- R134a refrigerant for high ambient temperature operation and the lowest GWP of all contemporary refrigerants

- Integrated circulation pump

- Comprehensive 12 months warranty on all parts and labour

- Highly accurate electronic controller

- 316SS plate heat exchanger evaporator

- Comprehensive factory testing before dispatch

Chiller Application

Industrial process chillers are designed to circulate water to a heat producing process via a water pump. The water brings the heat back to the chiller where the compression cycle cools the water before it is returned to the heat process.

Pump data

Pump data

| Pump model |

Current draw – 3 Ph |

Motor rating – kW |

Weight |

| P7 |

3.0 |

1.2 |

28.4 |

| P8 |

4.6 |

2.2 |

35.9 |

| P9 |

|

|

|

| RPM |

2900 |

|

| Approvals |

CE, WRAS, ACS, TR, EAC |

|

| Housing |

Cast iron |

|

| Impeller |

Stainless steel 316 |

|

Process chillers are typically not for potable water applications although the chiller can be designed to supply potable water.

All Thermex chillers up to 50kW are supplied with a buffer tank – the buffer tank is an important feature in all chillers and the bigger the better. The buffer tank in a process chiller has many benefits such as

- helping protect the compressor from excessive starts

- preventing thermal spikes impacting on the compressor

- allows closer temperature tolerance to the process

- having stored chilled water to allow a managed shut down of a process should there be a problem with the cooling cycle

- allows for a vented design and prevent the need for a hydronics kit

All Thermex process industrial chillers are supplied with high efficiency scroll compressors supplied by Copeland. The scroll compressor is the latest in compressor technology

All Thermex water chillers use R134a refrigerant – R134a is a contemporary refrigerant with a low global warming potential. R134a refrigerant also has the benefit of being a low-pressure refrigerant gas – this allows Thermex chillers to operate in extreme ambient conditions- up to 52°C. Chinese and European manufactured chillers are rated at 35C ambient condition and are generally supplied with condensers that are not suited to these extreme conditions.